JUPITER

Superior Process Control and Automatic Defect Detection Solution

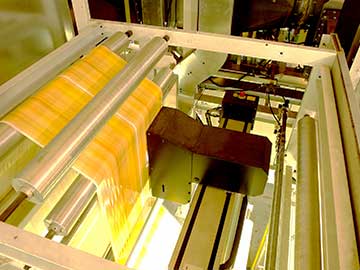

Uniquely designed for packaging web printing applications, AVT’s Jupiter gives you all the tools you need to guarantee comprehensive process control.

Jupiter’s advanced automatic detection software module visually inspects printed materials on the press, automatically detecting imperfections in real-time. When it comes to delivering quality print results, Jupiter gets the job done – every time!

Best-in-Class Process Control

Today, Over 50% of all high-end inspection and quality assurance systems installed are AVT platforms. AVT's Jupiter is a truly advanced, affordable automatic defect detection solution designed exclusively for packaging web printing applications. Jupiter draws on AVT’s years of field-proven experience gathered through thousands of installations worldwide, continuous dialogue with printers and the leading R&D team in the industry.

Jupiter’s process control demonstrates exceptionally high sensitivity to ensure early warning of developing defects.

The system immediately detects defects before they are seen by the human eye, dramatically reducing costly waste. Jupiter’s unique automatic inspection software module and innovative display visually inspects all types of printed materials on the press, automatically detecting defects in real-time. What’s more, Jupiter enables significantly higher press speeds, supports all press types, models and materials, including transparent and flexible substrates commonly used in the packaging industry, and is available with a range of optional add-on modules.

That Meets the Eye

Jupiter’s unique strength lies in its ability to identify print defects before they are seen by the human eye, immediately alerting the press operator. The system visually indicates the position and the type of defect detected, displaying the defect on a novel split-screen monitor, alerting the operator as to the nature and location of every defect. Jupiter’s “dual mode” capability enables operators to view the live image on one screen and the defect image on a second screen.

By deploying this intuitive, easy-to-use human interface, the operator can immediately address the problem and correct the relevant defect source. All defects are marked and categorized by advanced detection algorithms, according to defect type and sensitivity level. Defects are then saved to libraries for future use and to ensure printing consistency - same job in different runs.

PROCESS ERROR DETECTION

-

Miss-Registration

Jupiter, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan çizikler tespit edilir, raporlanır.

-

Spot

Jupiter, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan noktalar tespit edilir, raporlanır.

-

Color Variation

Jupiter, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan renk çeşitleri tespit edilir, raporlanır.

-

Smears

Jupiter, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan renk - yazı kaymaları tespit edilir, raporlanır.

-

Streak

Jupiter, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan sislenme tespit edilir, raporlanır.

Built-in System Features

• HD Camera: Equipped with an advanced HD camera guaranteeing best screen image quality, coupled with the highest quality inspection of evolving print defects.

• Sensitivity Profiles: Saves the sensitivities of each job for the next similar job run; dramatically reducing sensitivity setup time and ensures uniformity between operators.

• Hazing/Haze View: Enables detection of very low contrast defects such as hazing or scumming as soon as they evolve. The haze view function allows users to clearly see hazing on clear film which otherwise cannot be seen or detected prior to lamination.

Optional Modules

Technical Specifications

| Automatic Inspection | |

|---|---|

| Maximum inspected (printed) width: | Standard: 1200mm / 47.24” Optional unlimited masters: 2600 mm / 102.36” (wider webs supported upon request) |

| Max. web speed support: | 650 m/min, 2132 f/min |

| Minimal detected defect area: | 0.023 mm² at 2% contrast (smaller defects detected at higher zoom/contrast) |

| Inspection modes: | Full repeat cover or user-defined inspection steps. |

| Substrate: | Supports all material types, including flexible and transparent films, foils, paper and cartons . |

| Camera & Optical Head | |

| Camera: | High-resolution, 3-chip digital color camera. |

| Resolution: | 1392 x 1040 x 3 |

| Field of View (@ zoom x1): | 240mm X 180mm, 9.44” x 7.08” |

| Zoom: | Up to x16 optical zoom. |

| Calibration Mechanism: | Integral dedicated self-calibration H/W unit. |

| Additional Specifications | |

| Configuration: | Innovative ergonomically-designed console or integration into the press control console. |

| Defect detection software: | Jupiter Advanced Automatic Inspection software module. |

| Monitors: | 24’’, TFT, high-resolution monitors. |

| User interface: | Dedicated keyboard and mouse. |

| Languages supported: | Multilingual MMI capability. |

For information about the product, please contact us.

Gallery

© Copyright 2019 dunyaca.com.tr All Rights Reserved.