TITAN

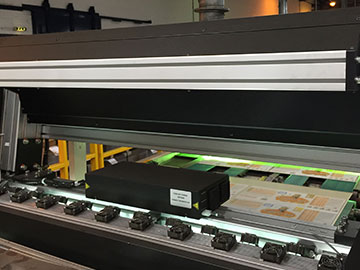

100% print inspection for metal decorating applications

Ensure your print quality and reduce your total costs by installing a 100% automatic print inspection solution on your press.

With AVT, the market leader for print inspection and color control in the packaging market, you can gain more production time on your press by reducing the total set-up time of the press while matching the quality standards of the market and reducing the total production waste.

100% Inspection to fulfill market needs

Control the Process, Provide Excellent Quality and Reduce Costs

Titan provides 100% inspection of every print defect right on time, to better control the printing process, reduce waste and increase quality.

The Titan best in class quality assurance platform - ensures detection and traceability of every printed metal sheet. All important print production defects are detected and traced during the production stages. A uniquely flexible design supports any type of metal decorated sheets and any type of application. All of these functions, along with the easy upgrade abilities, maintain your investment and market competitiveness.

Global approach: any language and any information can be printed

Titan provides a PDF format comparison with your print in order to allow customers to be able to print variable information and to support production of different languages.

No need to teach your operator new languages in order to avoid mistakes and to expand your business into new markets.

100% quality assurance based on vast experience and thousands of installations

Years of research, development and experience have been invested in Titan to achieve the most advanced detection capabilities available on the market.

Backed by AVT's vast experience and leadership of over two decades in print inspection, Titan is based on top sensing technologies and intelligent algorithms nevertheless it is very easy to use.

Each defect is classified by type and presented on screen with its precise location indicated on the full metal sheet. The system identifies process problems that can be fixed by the operators as soon as they evolve, as well as eject and mark defective sheets automatically.

process defect detection

-

<

<Scratches

Titan, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan çizikler tespit edilir, raporlanır.

-

Spots

Titan, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan noktalar tespit edilir, raporlanır.

-

Color variations

Titan, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan renk çeşitleri tespit edilir, raporlanır.

-

Mis-Registrations

Titan, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan renk - yazı kaymaları tespit edilir, raporlanır.

-

Scumming

Titan, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan sislenme tespit edilir, raporlanır.

-

Physical damage

Titan, üst düzey algılama teknolojileri ve akıllı algoritmalarıyla, baskı işlemi devam ederken oluşan fiziki hasarlar tespit edilir, raporlanır.

Productivity Driven

• Printing defects are detected and shown on screen, immediately as they start to evolve.

• Early warning of evolving defects enable the operator to react fast and fix the problem before production waste is created.

• Defective sheets can be ejected automatically to the waste bin or diverted automatically for additional verification.

• Enhanced printing quality.

• Reduce waste and production costs.

• Generate new business opportunities.

• Guarantee your competitive advantage and leadership.

Optional Modules

For information about the product, please contact us.

gallery

© Copyright 2019 dunyaca.com.tr All Rights Reserved.