ARGUS

Combination Inspection Solution for Process & Quality Control

Introducing Argus Turbo, AVT’s flagship system that delivers a unique combination of automatic 100% print inspection and quality control.

Backed by AVT’s pioneering vision technologies, Argus Turbo raises the bar on in-line process control and quality assurance, resulting in the delivery of high-quality print jobs.

All the tools you need for 100% quality assurance and process control!

Today, over 50% of all high-end inspection and quality assurance systems installed are AVT platforms. AVT’s Argus Turbo is a fully automatic Quality Assurance and Process Control system designed to deliver unparalleled quality and control of all your print jobs.

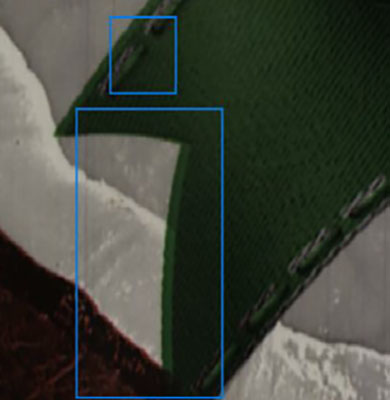

To achieve high-quality results, the system combines two advanced sensing technologies: 100% inspection of the web 100% of the time at the highest possible speeds, while in parallel, an area-based camera zooms-in to inspect various locations of interest, at high-resolution. This unique combination results in superior coverage and process control in parallel.

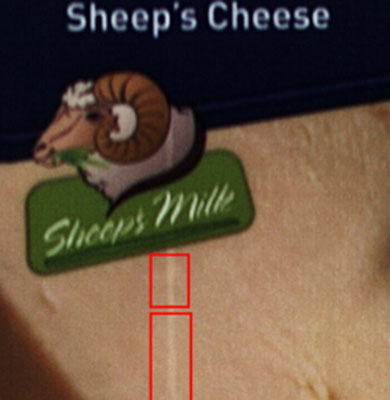

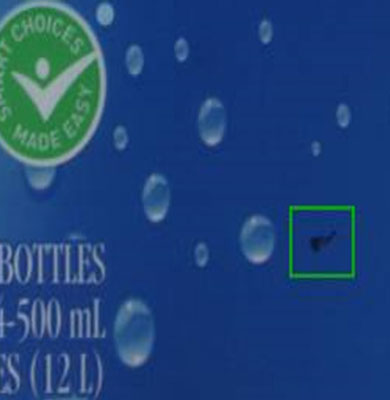

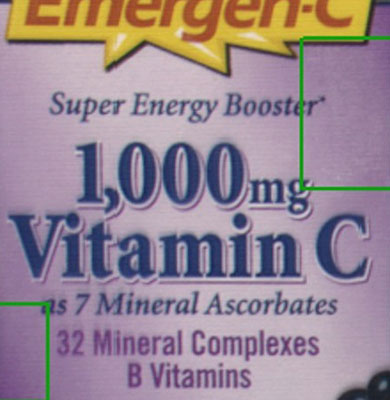

To guarantee consistent print quality, the system visually inspects all types of print defects, including color variations, mis-registration, streaks, splashes, misprints and more. Argus Turbo visually indicates the position and type of defect, enabling operators to quickly address problem areas and correct the relevant defect source. The system visually inspects all types of printed materials, including standard transparent and flexible substrates, identifying random and process print problems before they result in waste and customer rejection.

Both repeating and random defects are automatically marked according to selected quality thresholds, and if necessary, the high-resolution matrix area camera is pointed to the suspected defect location for further investigation of the problem. A report is issued at the end of the roll showing the defect location, including images of the defect and its corresponding master. This enables intuitive tracing of the waste during the finishing process, before sending printed job to the customer.

AVT Process Control solutions suite (“Jupiter”) can be easily upgraded to the Argus Turbo configuration.

Raising the Bar: Workflow, Archiving & Reporting

Argus Turbo raises the bar on your on-press and post-press production workflow. Equipped with an innovative built-in PrintFlow module, the system effectively handles job and data archiving and reporting.

An integral part of the production workflow, operators use in-line reporting to review job/order/roll reports, edit and export final reports to digital files, or use the AVT WorkFlow Link to automatically connect to rewinders or slitters and efficiently remove defective material prior to shipment.

Quality reports with detailed defect images help operators identify problem areas, and more importantly, assist in the decision-making process to enhance overall production and deliver quality print jobs.

The system’s PrintFlow Manager collects relevant PrintFlow data from multiple systems, so that managers and key personnel can easily monitor, analyze and

process defect detection

Unrivalled Print Quality

• Delivers 100% quality assurance and print process control.

• Detection and alerts on a wide range of print defects.

• Marks all defects for further analysis, archiving and reporting.

• Presets system sensitivities for individual print jobs.

• Supports all web press substrates/applications.

• Ensure consistent print quality on every job.

• Increase overall press productivity.

• Gain rapid return on investment (ROI).

• Save valuable time with fast press set-up deployment.

• Reduce waste, resources and production costs.

• Prevent customer rejections.

Unique Print Inspection Process

• Fully automated inspection process.

• Intuitive user interface with easy on-line guide, minimizes job set-up

• Detects critical defects, while eliminating false alarms

• Categorizes defects according to type with easy on-screen view

• Indicates precise defect location on full repeat image

• Connects to print house ERP for seamless job download

• asily upgradable software-driven platform

CAMERA COMPARISON

220microns at 798 m/min regular camera

220microns at 798 m/min “Turbo Engine”